All compliant with D.Lgs.81/08, UNI EN 795, and UNI 11578: safety and durability even on prefabricated roofs.

Relying on Spider Lifelines means working with a partner that combines technical expertise and passion for working at height safely.

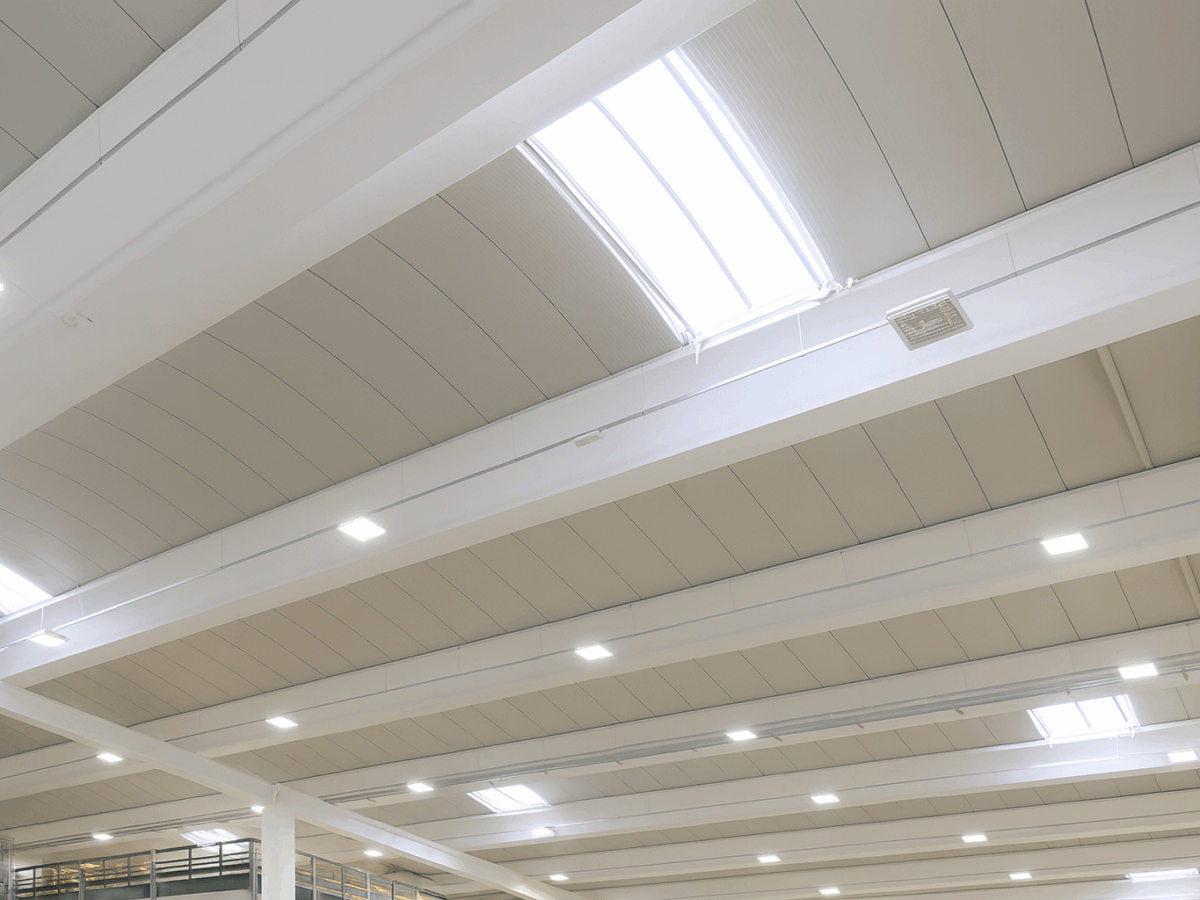

Our internal technical office develops each project with millimeter precision, analyzing profiles, thicknesses, and slopes of your prefabricated roof to identify the ideal anchor points without drilling. Our team of certified installers works quickly with minimal impact on the roof, using clamp-on brackets and ballasted systems designed to glide along metal ribs.

And we don’t stop at installation: we offer a scheduled maintenance service with certified load tests and photographic reports, ensuring maximum safety and durability of your fall protection system over time.

Every installation on prefabricated roofs must comply with these standards to ensure operator protection and preserve the roof covering. Spider Lifelines supports you in every phase: from design to testing, with complete documentation.

Profiled metal surfaces become dangerous when wet or icy.

Point loads can bend or damage sheets.

Loss of balance on inclined and unprotected slopes.

Tools or debris may slide along the profiles.

Aggressive atmospheres erode anchors and metal supports.

Improper installations compromise stability and safety.

No: we use clamp-on brackets that attach to ribs without drilling.

Protective plates ensure more than 10 kN of holding capacity.

Yes: we recommend annual inspections with certified load tests.