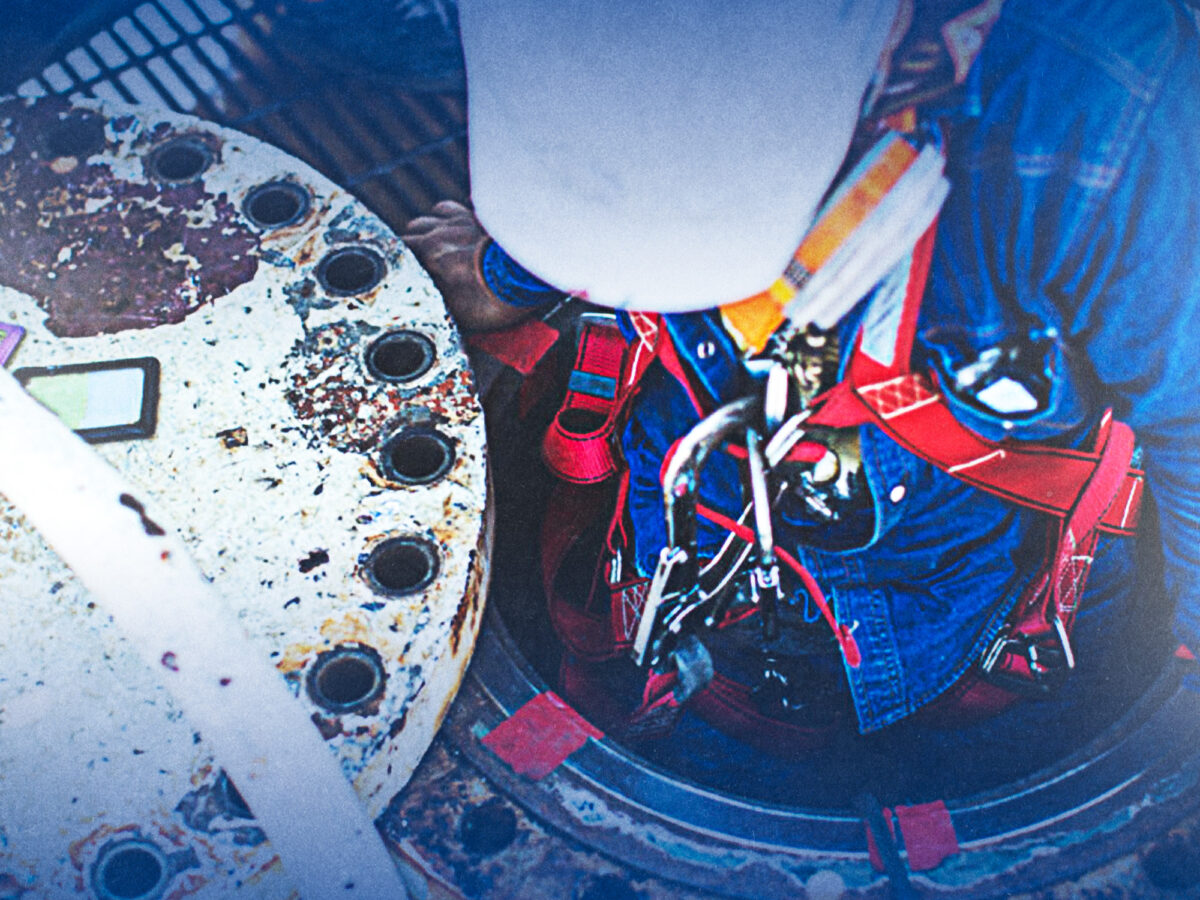

Confined spaces and spaces suspected of contamination represent high-risk working environments, characterized by restricted or difficult access, insufficient ventilation, and the potential presence of hazardous atmospheres. In such environments, the correct design and installation of fall protection systems, integrated with access and rescue solutions, is essential to ensure operator safety and compliance with applicable regulations and standards.

Pursuant to Presidential Decree (DPR) 177/2011, and in line with INAIL technical guidelines and UNI 11958:2024, a confined space is defined as an area exhibiting one or more of the following characteristics:

By way of example, confined spaces include:

silos, cisterns, tanks, underground basins, wells, ducts, tunnels, wastewater treatment plants, pipelines, and inspection chambers.

Activities carried out in confined spaces expose workers to a combination of often concurrent risks, including:

The management of these risks requires an integrated technical approach, including fall arrest systems, rescue devices, and dedicated emergency procedures.

Any operation carried out in a confined space must be preceded by a specific risk assessment, taking into account the geometric characteristics of the space, the activities to be performed, and the internal atmospheric conditions.

The selection of collective protective equipment (CPE) and personal protective equipment (PPE) must be consistent with the outcomes of the risk assessment and compliant with the requirements of DPR 177/2011 and the technical criteria defined by UNI 11958:2024.

Collective protection measures represent the primary means of risk reduction and may include, depending on the operational scenario:

Where residual risks cannot be eliminated through collective measures, the use of Category III PPE is required, selected according to operational conditions and planned rescue procedures. The main PPE used in confined spaces includes:

Our company provides integrated services and systems for safety in confined spaces and spaces suspected of contamination, supporting companies and clients throughout all phases of risk mitigation, in compliance with Legislative Decree 81/2008, DPR 177/2011, and UNI 11958:2024.

We carry out technical site inspections to assess environmental characteristics, operational methods, and specific risks, with particular focus on fall hazards and access and rescue operations.

We design customised fall protection, access, and rescue systems for confined spaces in accordance with UNI 11958:2024 and the applicable UNI EN standards.

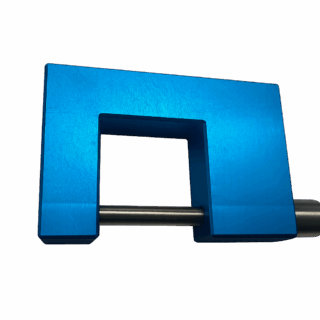

We manufacture and install fall protection systems, managing testing, certification, and technical documentation to ensure reliable solutions fully compliant with current regulations.

We deliver training courses and hands-on instruction for work in confined spaces, compliant with DPR 177/2011 and the new State-Regions Agreement, focusing on PPE use, operational procedures, and emergency management.

Through an integrated approach combining assessment, design, installation, and training, we support companies in the complete management of confined space safety, ensuring regulatory compliance and effective protection of workers.