How to ensure the safety of workers during routine and extraordinary maintenance operations on flat roofs?

In Italy, Legislative Decree no. 81 of 2008, known as the “Consolidated Law on Workplace Safety,” aims to establish uniform protection standards for workers across the national territory. This applies to all sectors, including maintenance and transit operations on flat roofs.

Sheet metal roofs represent a serious fall hazard for workers who need to intervene or even just transit on them. Therefore, it is necessary to provide adequate measures for fall prevention and protection in compliance with current regulations.

SPIDER can offer you custom design, turnkey supply, installation, and maintenance of any type of fall protection system.

If you have all the necessary information and documents click here

Falls: This is the greatest risk due to the slipperiness of the surface and potentially the most dangerous, especially in the presence of moisture and ice.

Falling objects: Objects falling from heights can cause serious injuries to workers below.

Equipment-related risks: Using unsuitable equipment or using it incorrectly significantly increases this risk.

Exposure to the elements: In addition to weather-related risks, it is crucial to pay attention to two more factors when working on sheet metal roofs:

High Temperatures → Sheets, especially dark-colored ones, absorb a lot of heat under the sun. Their temperatures can reach extremely high levels, causing severe burns on contact. This affects not only the skin but also the soles of shoes, which can melt or be damaged, compromising grip and increasing the risk of falls.

Glare Effect → The reflective surface of the sheet metal can cause glare, leading to temporary loss of visibility, disorientation, and visual fatigue. These effects make it much harder to accurately assess footholds and distances, significantly increasing the risk of slipping or tripping.

Securing sheet metal roofs requires a methodical and professional approach, divided into precise phases to ensure maximum effectiveness and compliance with regulations.

1. Inspection and Analysis

Everything begins with a detailed inspection of the roof. Our technical team takes precise measurements, evaluates the characteristics of the sheet metal (type, thickness, finish), and collects all relevant information. This phase is necessary to understand the specific needs of the roof and to carry out a custom design, optimized for the activities that will be performed on the roof.

2. Design of the Fall Protection System

The goal is to define the safest and most efficient fall protection solution. Access methods are determined, anchoring devices are strategically placed, and the most appropriate fixing techniques are selected, taking into account the integrity of the roof covering.

3. Professional Installation

Installation is performed by highly qualified personnel. Our team’s experience ensures precise and safe installation on any type of sheet metal roof. Advanced techniques are applied to fix the devices, minimizing impact on the structure and maximizing operational safety.

4. Certification and Handover

The final phase of the project is certification. Our staff provides a complete turnkey service, including all technical documentation and certifications required by law. This ensures the client receives not only a functional system but also full legal compliance, which is essential for safety and liability.

Depending on the roof covering and to ensure maximum safety and functionality, Spider offers a wide range of tested and certified products that can be fixed directly on the roof, providing an efficient solution for various types of roofs.

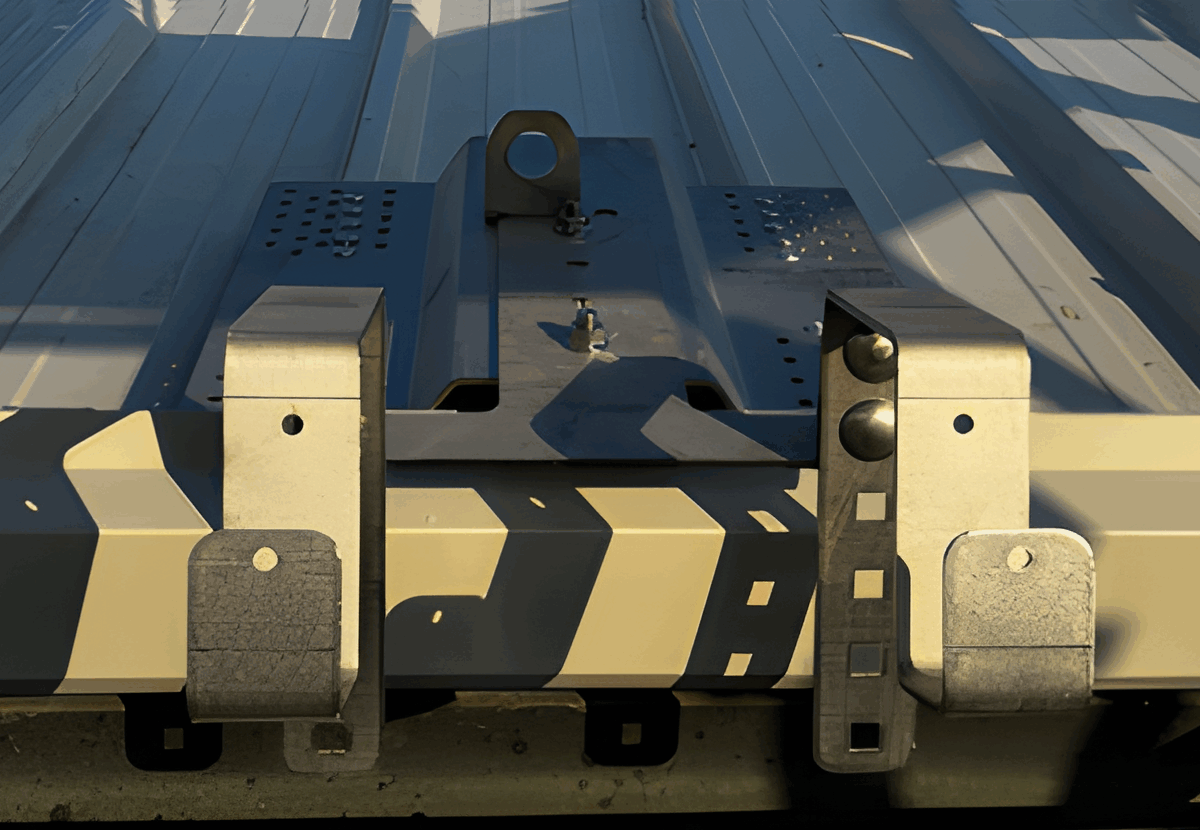

The main advantage of these products is that they do not require reaching the underlying structure. Installation takes place directly on the sheet metal using two main methods:

• Certified Rivets: The use of certified rivets ensures the highest quality fastening. In addition to being extremely robust, they are designed to create a perfect seal, essential for maintaining roof waterproofing.

• Special Certified Clamps: For sheets with folded joints, installation is done using special clamps that work directly on the metal fold, preserving its integrity and sealing.

Each of these fixing systems guarantees two fundamental benefits:

Simplicity and speed of installation, making the entire process faster and less invasive.

Guaranteed waterproofing; fastening with specific certified rivets ensures no leaks, keeping the roof fully waterproof.

The type and shape of the sheet metal are crucial for correctly selecting and installing a lifeline system. Therefore, it is essential to choose an anchoring system compatible with the specific characteristics of the roof.

Thanks to a wide range of products, SPIDER offers lifeline solutions suitable for every type of roof, including:

• Simple sheets

• Insulated sheets

• Folded sheets

These standard systems, available in aluminum (up to 5/10 thickness) or steel (up to 4/10), are designed to be fixed directly onto the sheet metal. This innovative technology avoids the need to anchor to the underlying structure, simplifying installation while maintaining full roof waterproofing.

Access to heights using lifelines is governed by precise regulations and safety procedures to ensure maximum worker protection. The correct approach is based on detailed planning and the use of appropriate equipment. It is essential to plan safe access to the roof from the start, not only for system installation but also for all future maintenance activities. This ensures that every task can be performed safely and in full compliance with regulations.

• Roof access points must be safe and clearly marked in the Technical File. They are often equipped with an information plate showing the fall protection system data and the date of the last inspection.

• Workers must use PPE compliant with regulations, such as harnesses, lanyards, connectors, and energy absorbers. These devices must be periodically inspected and worn correctly.

• Once at the access point, the worker connects to the lifeline before proceeding. They must remain attached to the system throughout transit and while stationed on the roof, following the designated paths and instructions.

• All workers accessing the roof must have received specific training and practical instruction on the correct use of fall protection systems and related PPE.

SPIDERWIKI – Regulations in Italy and Europe for Work at HeightRegulations on working at height are a crucial topic, especially in Italy and Europe, and include a series of rules designed to ensure worker safety. These regulations may seem complex, but don’t worry—we’re here to help you understand them! First, it’s important to note that these rules were created with one main goal in mind: your safety. These regulations include requirements for training, safety equipment, and standard operating procedures. For example, it may be necessary to complete specific training or use personal protective equipment (PPE) such as safety belts or harnesses. But how are these regulations applied in practice? And how can they affect your daily work? This is where our team of experts comes in. We are here to help you navigate the maze of laws and rules to ensure you can work safely and compliantly. If you want to know more or need help understanding how these regulations apply to your specific sector or situation, do not hesitate to contact us. We can provide personalized advice, answer your questions, and guide you step by step. |

Work at Height Regulations – Italy

Legislative Decree 81/08 – Annex XXI

Regional Regulations on Safety Rules for Work at Height

Technical Standards – Italy

UNI 11900:2023 – Non-regulated professional activities – Installer of anchoring systems – Requirements for knowledge, skills, autonomy, and responsibility

UNI 11560:2022 – Permanent anchoring systems on roofs – Guide for identification, configuration, installation, use, and maintenance

UNI 11578:2015 – Anchoring devices for permanent installation – Requirements and test methods

UNI EN 795/2012 – Personal fall protection devices – Anchoring devices. Fixed Anchors, Mobile Fixed Anchors, Flexible Line Anchors, Rigid Line Anchors, Weighted Point Anchors

Work at Height Regulations – Europe

Directive 2001/45/CE

Directive 89/656/CEE (Use of Personal Protective Equipment)

It is important to note that these EU directives are implemented in member states through national legislation.

Remember, specific regulations may vary from country to country within the EU, so it’s important to consult local laws.

Smooth metal surfaces become extremely dangerous when wet or frosty.

Folds or ripples can reduce anchor stability.

Loss of balance on steep roof panels.

Tools and debris can slide down the metal surface.

Marine or industrial atmospheres accelerate fastening wear.

Incorrect installation or lack of maintenance weakens safety.

No: we use clamp-on brackets that attach to the ribs without drilling.

Protective plates guarantee over 10 kN of resistance.

Yes: we recommend annual checks with certified load tests.